Top-Rated Welding Inspection Service for Manufacturing Facilities

Top-Rated Welding Inspection Service for Manufacturing Facilities

Blog Article

Comprehending the Different Sorts Of Welding Techniques and Providers Offered

Introduction of Welding Methods

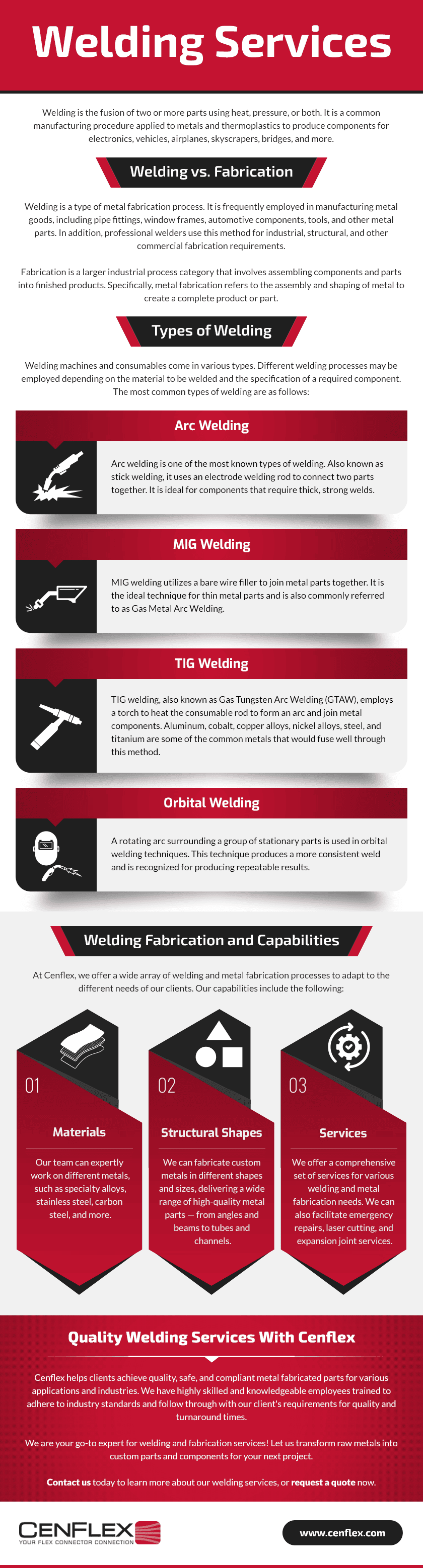

Welding methods include a diverse series of methods utilized to sign up with materials with each other permanently. One common method is arc welding, which includes creating an electrical arc between the base and an electrode product to thaw and fuse them with each other. This method is functional and can be utilized with numerous metals, making it one of one of the most widely utilized welding procedures.

In addition, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a specific and clean welding method that makes use of a non-consumable tungsten electrode to develop the weld. TIG welding is generally made use of for thinner materials and offers outstanding control over the welding process. In general, recognizing these different welding strategies is necessary for picking one of the most suitable method for different jobs.

Commonly Made Use Of Welding Techniques

One of the most extensively used strategies is Gas Steel Arc Welding (GMAW), likewise recognized as MIG welding. Another usual approach is Protected Steel Arc Welding (SMAW), or stick welding, which makes use of a flux-coated electrode to create the weld - Welding Inspection Service. Flux-Cored Arc Welding (FCAW) is commonly utilized in commercial settings due to its high welding rate and mobility.

Advanced Welding Services

Structure upon the foundation of generally made use of welding approaches, the world of sophisticated welding services encompasses sophisticated techniques and modern technologies that press the limits of accuracy and efficiency in material signing up with processes. Advanced welding services typically involve specialized approaches such as laser welding, electron beam welding, and rubbing stir welding. Friction mix welding, a solid-state joining procedure, enables the welding of materials that are testing to fuse making use of traditional methods, like aluminum and copper.

Specialized Welding Strategies

Another specialized welding method is laser beam article source welding, where a very concentrated beam is used to sign up with metals with marginal heat-affected areas and distortion. This approach is frequently used in markets requiring high precision and sanitation, such as electronics and clinical tool manufacturing. In addition, eruptive welding is an unique strategy that uses regulated nitroglycerins to bond different metals together, developing trusted and solid joints. These specialized welding methods showcase the variety and development present in the field of welding, supplying solutions for a variety of industrial applications.

Selecting the Right Welding Process

With various welding methods readily available, it is critical to take into consideration aspects such as the kind of metal, density, joint style, and wanted end outcome when selecting the best welding procedure. Amongst the typical welding approaches are Gas Metal Arc Welding (GMAW), Protected Steel Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) GMAW, additionally recognized as MIG welding, is suitable for welding thin to thick steels and is functional in different placements.

Verdict

In verdict, comprehending the various sorts of welding techniques and services readily available is necessary for picking the right method for a specific project. By understanding the frequently utilized welding approaches, advanced welding services, and specialized techniques, individuals can make educated choices to guarantee the success of their welding tasks. It is essential to think about variables such as materials, job demands, and budget plan when choosing one of the most suitable welding process.

From traditional approaches like stick welding to innovative processes such as laser welding, the world click here for more info of welding uses a multitude of choices for joining steels with each other.Furthermore, TIG welding, or Gas Tungsten Arc Welding (GTAW), is a accurate and clean welding method that uses a non-consumable tungsten electrode to create the weld. Advanced welding services frequently include specialized approaches such as laser welding, electron beam of light welding, and rubbing stir welding. Among the typical welding why not try here techniques are Gas Steel Arc Welding (GMAW), Secured Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW) By being conscious of the typically used welding approaches, advanced welding services, and specialized strategies, people can make enlightened decisions to ensure the success of their welding jobs.

Report this page